Electronic semiconductor wastewater mainly from the production of electronic semiconductor materials for the production of cyanide wastewater and other comprehensive wastewater, according to the information provided by the owner and our analysis of the water quality, the need for biochemical effluent into the zero-discharge system, the water quality to meet the requirements of the RO membrane. Electronic semiconductor wastewater containing cyanide wastewater system new biochemical process using AO biochemical treatment system, water from the original system of physical and chemical treatment section of the intermediate pool after the sedimentation tank, biochemical effluent into the original system of sand filters.

Pump supporting: electronic semiconductor wastewater treatment treatment project

Project Customer: Changzhou Electronic Industry Co.

Actual flow: 200T/D

Actual head: 6m

Water body analysis: Acid-containing wastewater and other comprehensive wastewater (PH = 4)

Temperature of water body:50℃

Structure: centrifugal self-priming

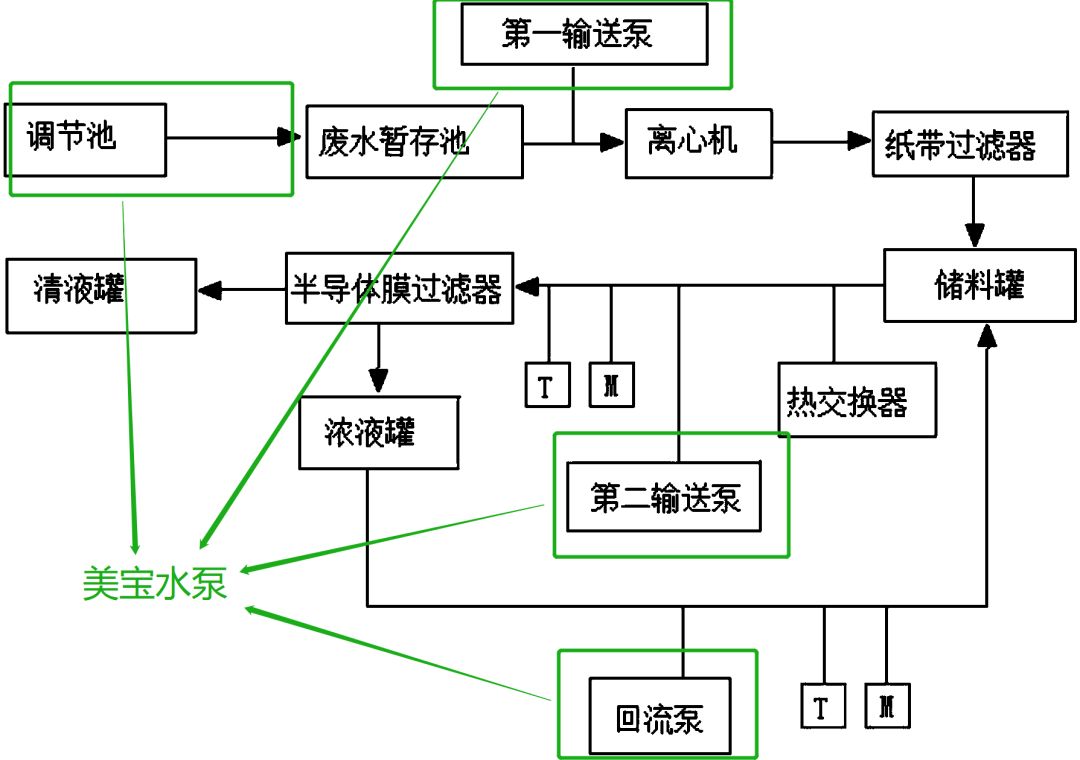

Application process: acid wastewater and other comprehensive wastewater transport cycle

Customer requirements: corrosion resistance, can be used with filters

Media concentration: 20% sulfuric acid, 10% phosphate

1、Confirm the pump type

According to the customer site process to determine the type of pump: customers need to use the pump in the acidic wastewater and other comprehensive wastewater transport cycle, first of all, we can determine that our pumps can be used: Mabel MK acid and alkali self-priming pumps and MC acid and alkali chemical pumps.

2、Determine the pump material

According to the type of media, temperature, concentration to determine the pump material: customer site water is mainly: acidic wastewater and other comprehensive wastewater (PH = 4); temperature of 50 ℃, the main medium for 20% sulfuric acid, 10% phosphate.

According to the medium of PH acidity, temperature and concentration, we recommend the customer pump material selection: FRPP.

3, determine the pump power

According to the actual head flow to determine the power of the pump: the customer needs the actual head of the pump 6M, the actual capacity of 200t / d, so we recommend the pump power: 2.2KW.

4、Determine the specific model

According to the customer's other requirements to determine the specific model: the customer requires the pump corrosion resistance, can be used with the filter. Combined with the material, power, process, we recommend to customers: can be idle acid and alkali self-priming pump. Specific model: MK-50032NBH-CCH, material: FRPP, power: 2.2KW.