Wastewater treatment is an indispensable part of chemical production, and the chemical conditioning tank, as an important part of the wastewater treatment system, has a direct impact on the efficiency of the entire wastewater treatment process. Choosing a suitable chemical conditioning tank lifting pump is essential to ensure the smooth operation of wastewater treatment. Mabel Pumps, with its excellent product performance and rich industry experience, has provided many chemical companies with efficient lifting pump solutions.

The water quality characteristics of the chemical conditioning tank are mainly manifested in the following aspects:

Complex composition: chemical wastewater may contain a variety of organic matter, inorganic matter, heavy metals and other pollutants, these pollutants are diverse and complex.

High concentration: the concentration of pollutants in chemical wastewater is usually high, which makes wastewater treatment difficult.

Large fluctuation of pH value: Due to the chemical production process may use a variety of acids, alkalis and other chemicals, resulting in large fluctuations in the pH value of wastewater.

Large temperature changes: the temperature of chemical wastewater may vary due to different production processes, which requires high performance of the pump.

Chemical conditioning tank is widely used in the following areas of wastewater treatment process:

Petrochemical: petrochemical enterprises in the production process will produce a large amount of wastewater, through the chemical conditioning tank for treatment, to ensure that the wastewater discharge standards.

Fine chemical industry: fine chemical industry wastewater composition is complex, need to be pre-treated through the chemical conditioning tank, to provide good conditions for the subsequent treatment process.

Pesticides and fertilizers: pesticides and fertilizers produced in the production process of wastewater on the environment and human health hazards, through the chemical conditioning tank for treatment to reduce the toxicity of wastewater.

In the selection of chemical conditioning tank lifting pump, should fully consider the water quality characteristics and application areas, to ensure that the pump's performance can meet the actual demand. Here are some suggestions:

Corrosion resistance: As chemical wastewater contains a variety of corrosive substances, lifting pumps should have good corrosion resistance to ensure long-term stable operation.

Flow and head: According to the size of the chemical conditioning tank and wastewater treatment process requirements, select the appropriate flow and head to ensure that the pump can meet the actual demand.

Material selection: give priority to stainless steel, alloy and other corrosion-resistant materials made of pump body, in order to improve the service life of the pump.

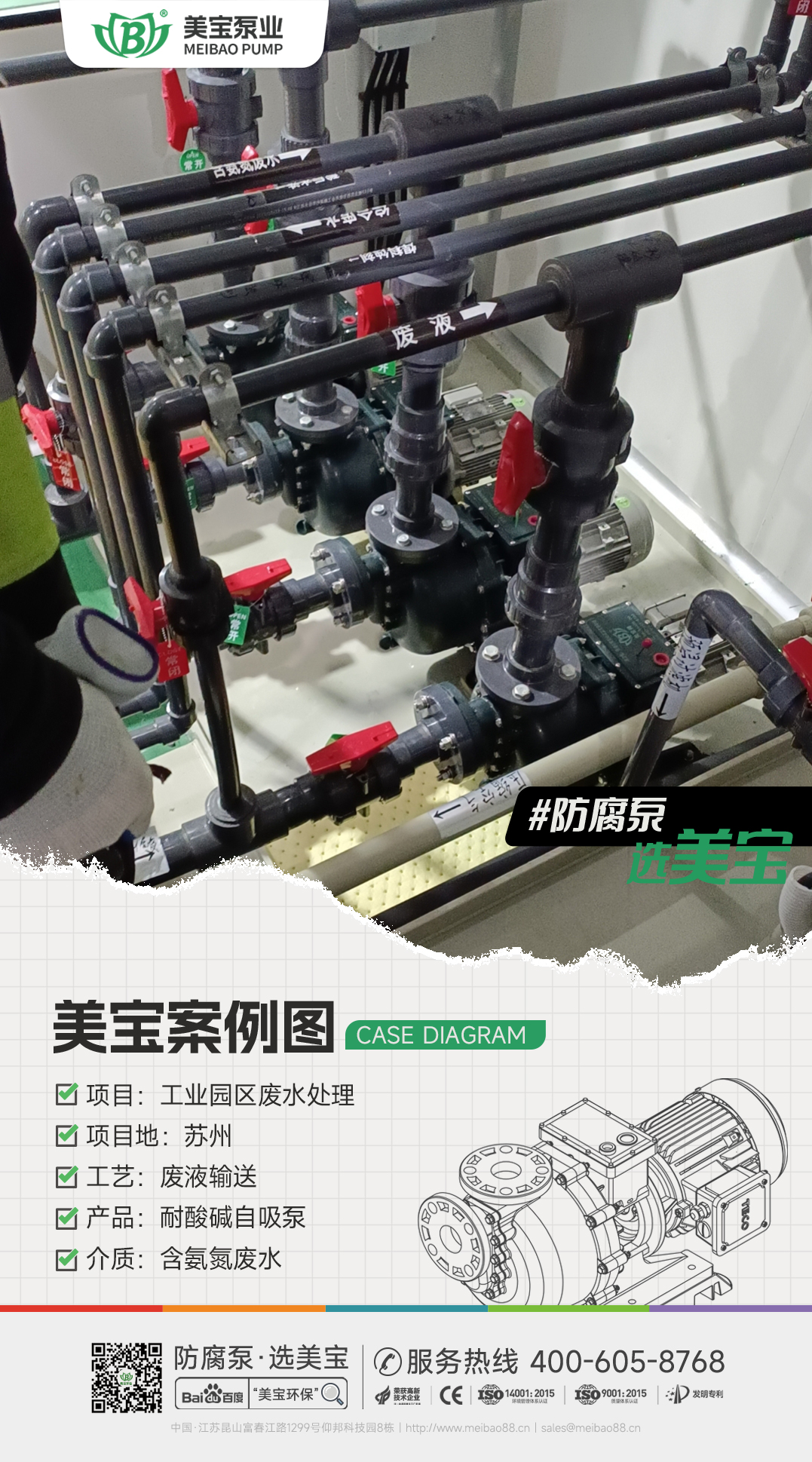

With its excellent product performance and rich experience in the industry, Mabel Pump has provided efficient lifting pump solutions for many chemical enterprises. For example, in the wastewater treatment project of a large petrochemical enterprise, Mabel Pump's lifting pumps have won high recognition from the customer by virtue of their excellent corrosion resistance and stable operation performance. In addition, Mabel Pump also provides customized solutions according to different customers' needs to ensure that every pump can perform.