The traditional submerged pump is suitable for conveying any concentration of strong acids, alkalis, salts, strong oxidants and other corrosive materials, but does not apply to the normal transport of flammable and explosive materials. In order to solve the problem of special media conveying, the new submerged pump has long been out of the blue, as a positive pressure conveying vertical pump, can effectively solve the problem of air resistance, cavitation, can be suitable for conveying flammable and explosive materials, although not suitable for conveyor belt particles of highly corrosive materials, but widely used in petroleum refineries, oil depots, chemical factories, pharmaceutical factories, factories, production lines, generator sets, and other special materials conveying places, the role of the great! It plays a great role. Today we will introduce some selection knowledge and skills of the submerged pump, is that we can be efficient and quick in the selection of the pump, less detour.

First, we first need to understand the liquid pump in the transport of materials in the explosion-proof grade, because it determines the liquid pump products have different structures, working principles, classification, scope of application, product advantages and disadvantages and mode of operation, so that the chemical and physical properties of the medium is the first thing we have to consider the first problem, which is the key basis for our selection!

Second, the field conditions required by the media flow rate values, flow rate is one of the important performance data for the selection of submerged pumps, which is related to the production capacity of the entire device and conveying capacity. When we choose the pump, the first large flow as the basis, while taking into account the normal flow, if there is no large flow, usually 1.1 times the normal flow as a large flow, that is, 1.1 times the required flow as to determine the final flow rate values.

Third, the field of environmental protection equipment and devices required by the system head, which is also an important performance data selection of submerged pumps, each pump has its own fixed head, the two must be matched, the normal pump head to be greater than the required head, leaving a certain margin.

Third, the submerged pump on environmental protection equipment and devices system piping layout conditions, which refers to the delivery height of liquid delivery distance liquid delivery towards and route, in order to carry out the system head calculation and cavitation margin of the calibration, to determine the relevant technical parameters, in order to facilitate the correct match.

Fourth, the liquid properties of the transport medium, including the name of the liquid medium, physical properties, chemical properties and other properties, of which, the physical properties of the temperature c, density d, viscosity u, the diameter of solid particles in the medium and the content of the gas, etc., which are involved in the environmental protection equipment and devices system of the necessary head, need to be calculated according to the effective corrosion allowance and the appropriate type of pump.

Pump and the chemical properties of the medium, which mainly refers to the chemical corrosiveness and toxicity of the liquid medium, whether it will be slow or violent chemical reaction with the pump material, whether the equipment as a whole or part of the damage caused by this is the selection of submerged pump materials and the selection of which shaft seal type is an important basis.

Fifth, affect the selection of submerged pumps and operating conditions there are many, for example, the operation of the liquid T saturated vapour force P, suction-side pressure PS, discharge-side vessel pressure PZ, altitude, ambient temperature operation is intermittent or continuous, the pump position is fixed or removable, etc., which are required to pump engineers and even if the demand side of the personnel to communicate together, and do further technical determination to determine, in order to decide! What kind of submerged pump is really suitable for the demand side of the pump.

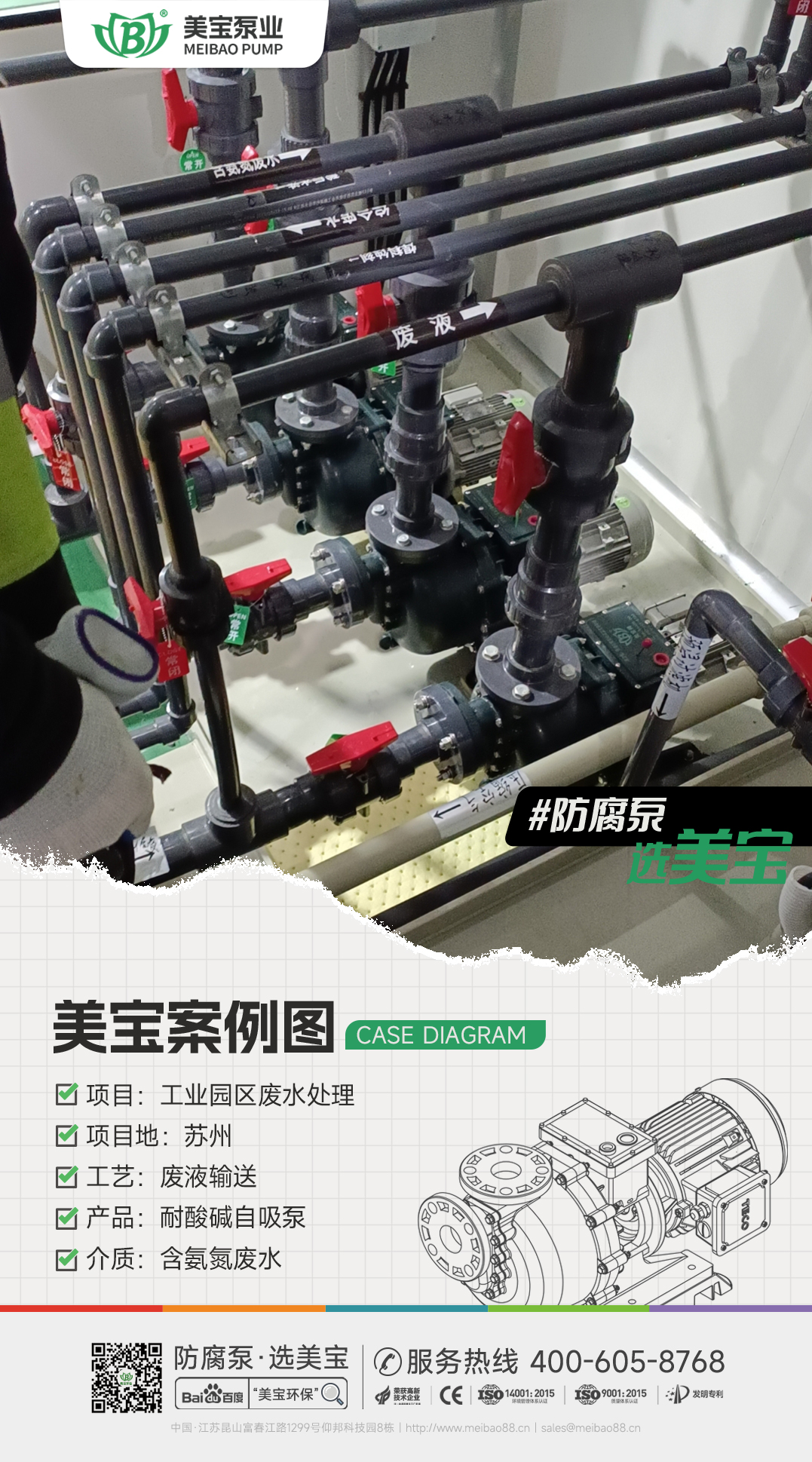

Meibao's anti-corrosion vertical pump, can be said to be the preferred product of the submerged pump, whether it is in the tank vertical pump, or outside the tank vertical pump, with its excellent performance, highly praised, whether it is in the tank submerged pumps or submerged pumps outside the tank, the performance is very good, has become the standard pumps in the chemical industry, if you have a selection of submerged pumps, feel free to consult with Meibao Environmental Protection.