In the chemical industry, triethylene glycol is widely and importantly used as a versatile compound. Due to its unique physical and chemical properties, triethylene glycol plays a key role in several fields. However, the transfer of triethylene glycol is a challenge that requires specialized knowledge and technology. Mabel Pumps provides a safe and efficient solution for the transfer of triethylene glycol with its specialized acid and alkali resistant pump technology.

The water quality characteristics of triethylene glycol are mainly characterized by high viscosity and stability. This makes it necessary to choose a pump that can adapt to its characteristics during the conveying process. The piston pump is the ideal choice for triethylene glycol transfer due to its great adaptability and stability. It is capable of stably conveying highly viscous triethylene glycol and maintaining stable pressure, ensuring quality and safety in the conveying process.

Triethylene glycol plays an indispensable role in several fields. In the oil and gas industry, triethylene glycol is used as a dehydrating agent to help remove water from gases; in the refrigeration and air conditioning industry, it serves as a heat transfer medium to improve refrigeration efficiency; and in the chemical industry, triethylene glycol is not only an important ingredient in the preparation of solvents and raw materials, but is also used in the textile industry for softening and finishing treatments. In addition, in the pharmaceutical and cosmetic industries, triethylene glycol is widely used as a raw material because of its moisturizing properties.

And in the environmental field, triethylene glycol plays an equally important role. It can be used as a fuel additive to improve the performance of fuel and reduce exhaust emissions; at the same time, as an oil well injection agent, triethylene glycol can increase the oil recovery rate of the oil field, improve the petrography of water wells, and contribute to the cause of environmental protection.

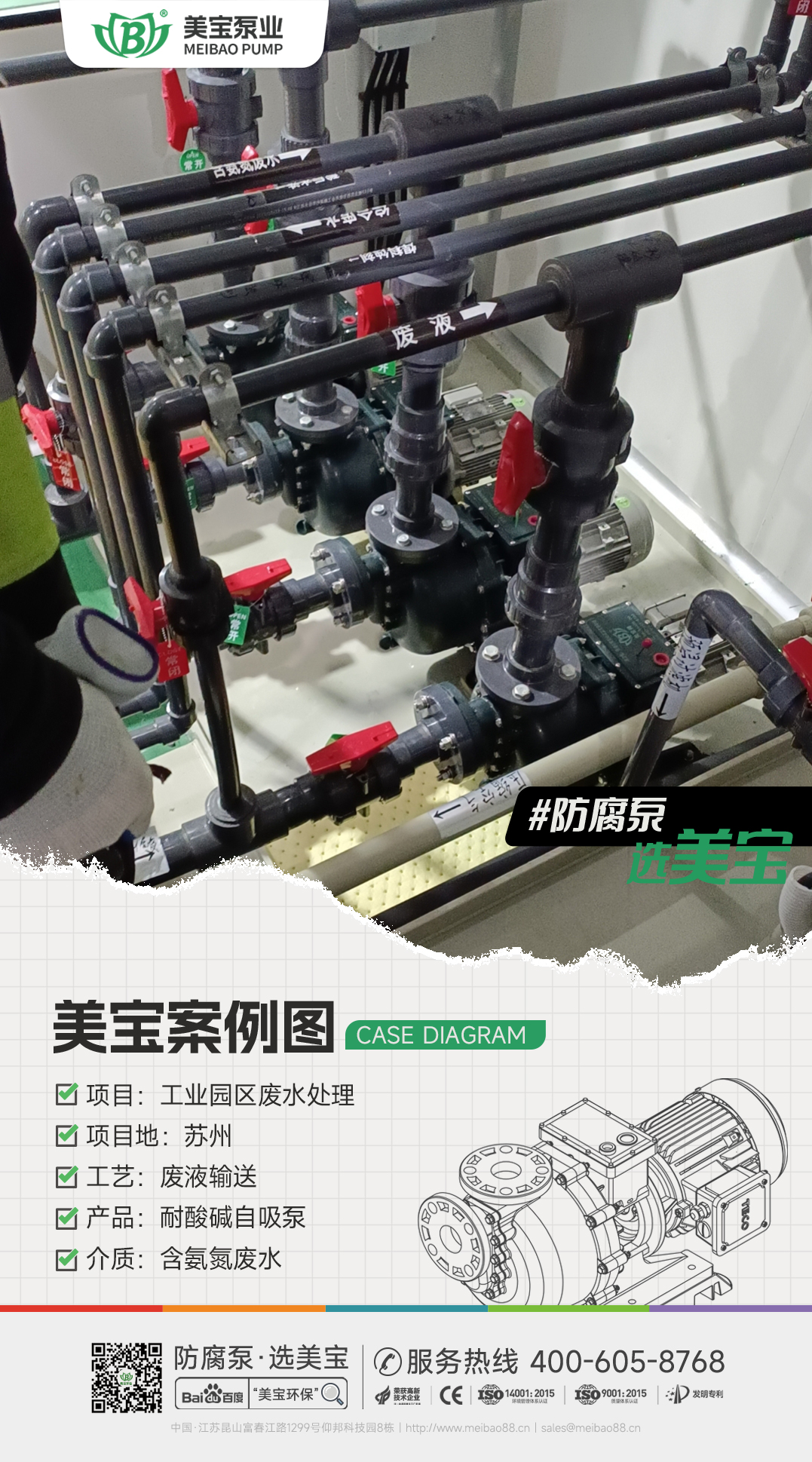

Facing the application demand of triethylene glycol in the field of environmental protection, Mabel Pump Industry, with its professional acid and alkali resistant pump technology, provides reliable solutions for customers. Our acid and alkali resistant pumps are made of high quality materials with good corrosion resistance and can run stably for a long time. Meanwhile, we optimize the design of the pump according to the conveying characteristics of triethylene glycol, which improves its conveying efficiency and service life.

In the actual case, a petroleum company used Mabel Pump's acid and alkali resistant pumps for triethylene glycol conveying. In the process of use, the pump shows excellent stability and durability, not only improves the conveying efficiency, but also reduces the maintenance cost. In addition, a pharmaceutical company also chose our acid and alkali resistant pumps for triethylene glycol conveying and preparation. In the process of use, the pump shows good corrosion resistance, ensuring the safety and quality of drug production.

In summary, Mabel Pump's acid and alkali resistant pumps are ideal for triethylene glycol conveying. We will continue to uphold the spirit of professionalism and innovation to provide customers with even better products and services, and contribute to the development of the chemical industry and environmental protection.