In the semiconductor manufacturing process, wastewater treatment is a critical part of ensuring the sustainability of the production environment and product quality. Semiconductor wastewater, due to its unique water quality characteristics, places higher demands on the performance of transfer pumps. Mabel Pumps, with its rich experience and technical strength in the field of fluid transfer, provides you with professional solutions for semiconductor wastewater transfer pumps.

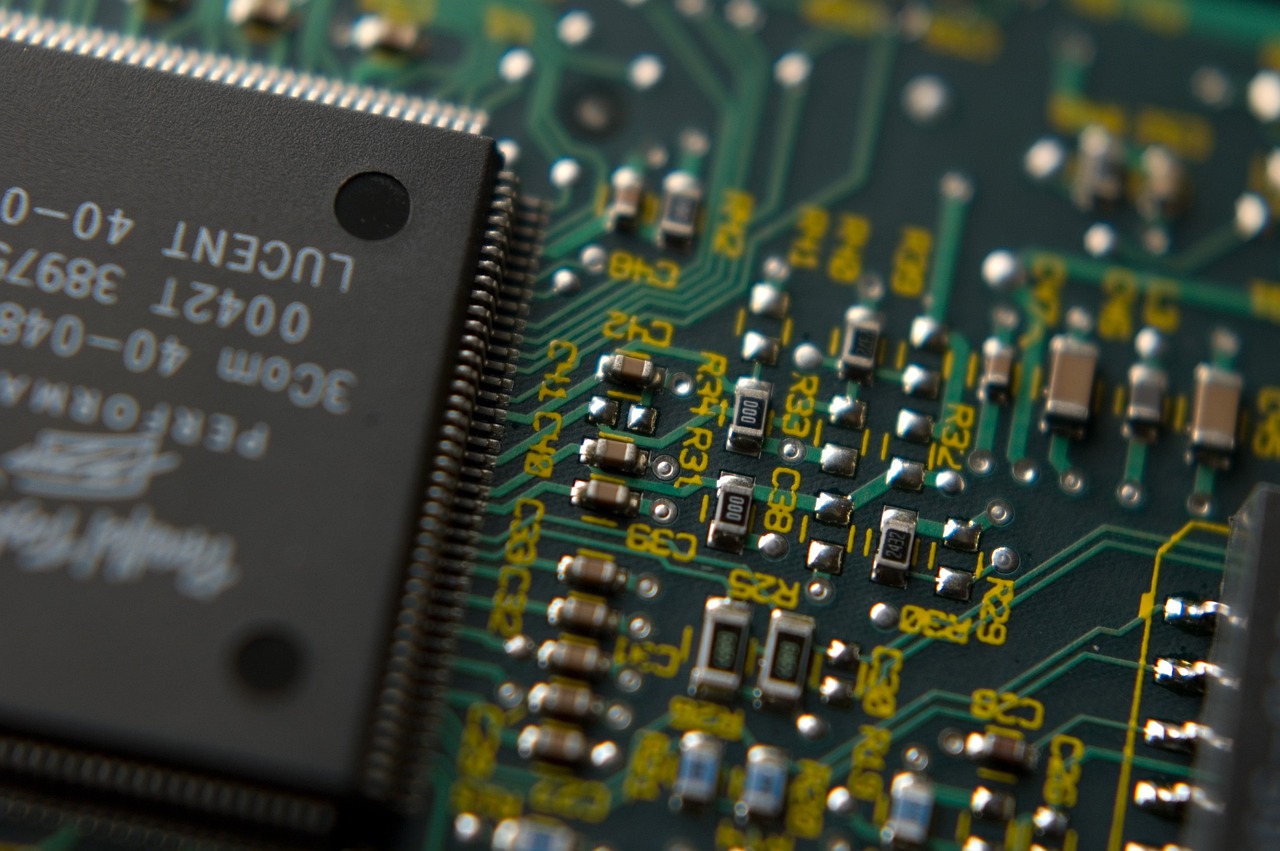

Semiconductor wastewater mainly comes from the semiconductor manufacturing process of cleaning, etching, grinding and other processes, its water quality characteristics mainly include:

High concentration of chemicals: wastewater contains a high concentration of acids, alkalis, organic solvents and other chemicals, these substances on the transfer pump materials and sealing performance put forward higher requirements.

Solid particulate matter: Wastewater may contain tiny solid particulate matter, such as abrasive powder, sand, etc., which pose a higher risk of wear and clogging of the pump.

Large temperature variations: Semiconductor wastewater may experience large temperature variations during treatment, ranging from ambient to high temperatures, which challenges the pump's heat resistance.

Semiconductor wastewater is mainly generated in the fields of semiconductor manufacturing, integrated circuit packaging and testing, and photovoltaic industry. These industries generate a large amount of wastewater during the production process, of which semiconductor wastewater has become an important branch in the field of wastewater treatment due to its special composition and treatment requirements.

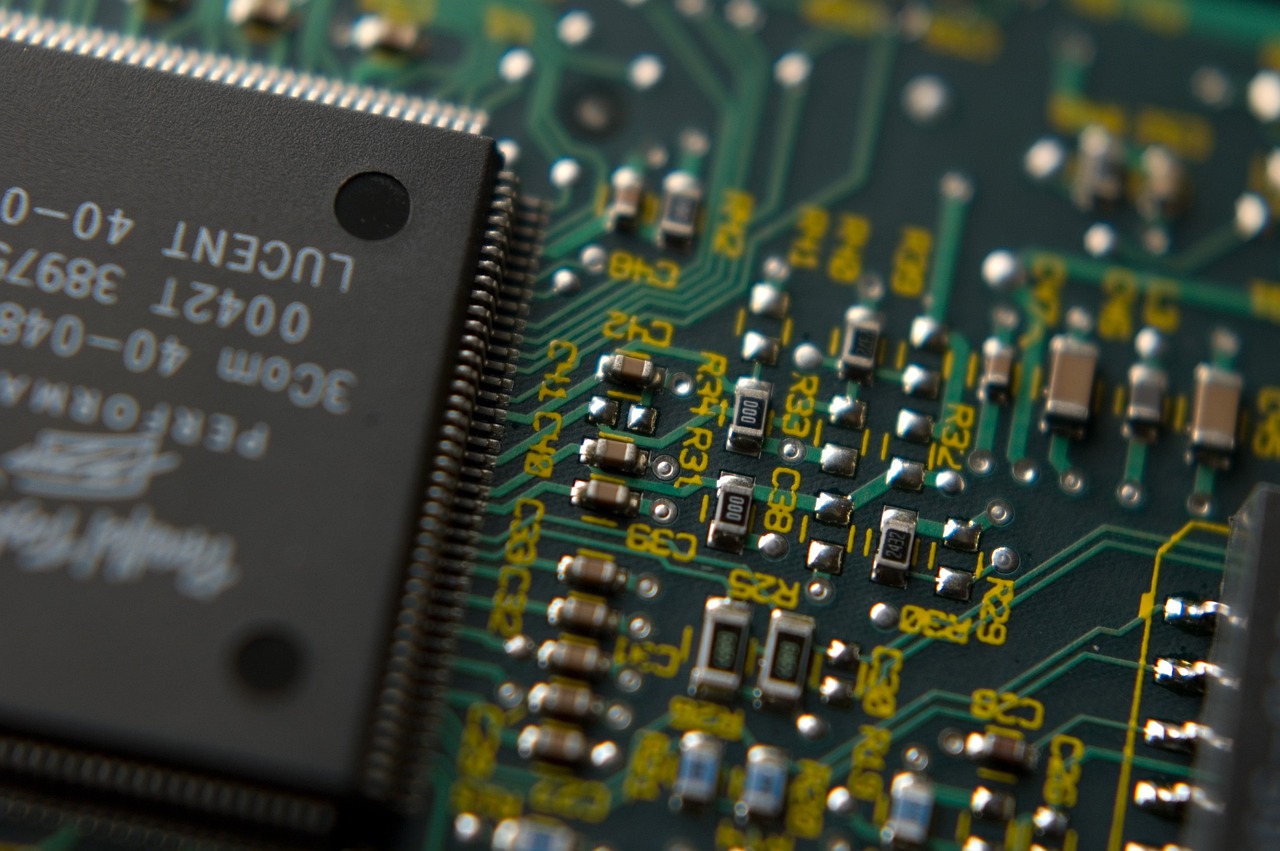

For the special water quality characteristics of semiconductor wastewater, Mabel Pump recommends the use of special pumps that are corrosion-resistant, abrasion-resistant, and high-temperature-resistant. Our semiconductor wastewater pumps have the following advantages:

Strong corrosion resistance: the pump body is made of high quality stainless steel or polymer material, which can resist the erosion of high concentration of chemicals in semiconductor wastewater and ensure the long-term stable operation of the pump.

Good abrasion resistance: the impeller and overflow parts of the pump are made of wear-resistant materials, which can withstand the abrasion of solid particles in the wastewater and reduce the damage and maintenance frequency of the pump.

Excellent high-temperature resistance: the design of the pump takes into full consideration of the temperature changes in the semiconductor wastewater treatment process, and the use of high-temperature-resistant materials and sealing structure ensures that the pump can still operate stably in a high-temperature environment.

In the semiconductor manufacturing field, Mabel Pump's semiconductor wastewater transfer pumps have been widely used. For example, in the wastewater treatment project of a well-known semiconductor manufacturer, the transfer pumps we supplied successfully transferred the wastewater to the treatment equipment, ensuring the wastewater treatment process to run smoothly. At the same time, the pump showed excellent corrosion and wear resistance during operation, which was highly recognized by the customer.

Semiconductor wastewater transportation is an indispensable part of the semiconductor manufacturing process. With professional technology and rich experience, Mabel Pump offers you the most suitable semiconductor wastewater transfer pump solutions. We are committed to providing customers with efficient, stable and reliable pumping equipment to help the semiconductor industry's sustainable development. We look forward to working with you to create a better future!