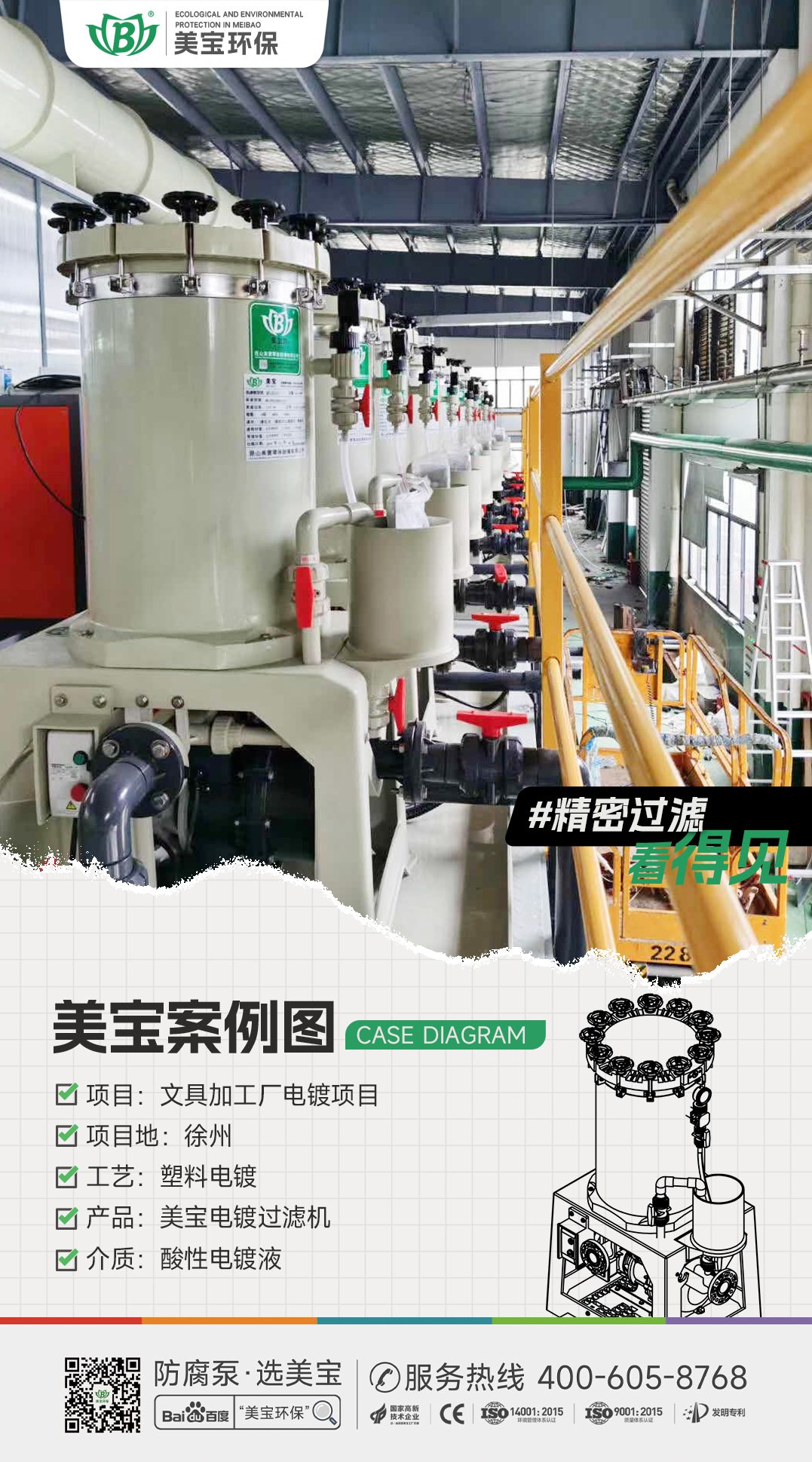

In the vibrant land of Xuzhou, a stationery processing plant is bringing unprecedented innovation and beauty to the market with its unique plastic plating process. Plastic plating, as a key technology to enhance the texture and aesthetics of the product, is gradually becoming the new favorite in the field of stationery manufacturing. And in this process change, Mabel plating filter with its excellent performance and tailor-made solutions has become the indispensable core equipment for the factory's chrome plating process.

Plastic plating, as the name suggests, is the process of covering a layer of metal film on the surface of plastic, especially the chrome layer, which can give the product a mirror-like luster and metal-like texture, greatly enhancing the grade and value of stationery products. However, this process has very high requirements on the purity, temperature control and filtration efficiency of the plating solution. Any tiny impurity or temperature fluctuation may affect the uniformity and adhesion of the plating layer, which in turn affects the final quality of the product.

It is based on the above challenges that Mabel's Plating Filter shines in the plastic plating process of stationery processing factories with its unique advantages.

High pressure resistance and production safety: Mabel electroplating filter adopts a molded barrel and foot base, designed with eight reinforcing ribs and a barrel thickness of up to 30mm, to ensure that it remains stable and reliable in high-pressure environments. This design not only improves the pressure resistance of the equipment, but also greatly reduces the risk of leakage due to welding problems, ensuring production safety.

High filtration precision ensures perfect plating layer: High filtration precision and wide filtration area make Mabel electroplating filter effectively remove tiny impurities and particles in the plating solution to ensure the purity of the plating solution. This is especially important for the plastic plating process, as a pure plating solution is the key to obtaining a uniform, smooth coating.

Easy operation and worry-free maintenance: According to customer needs, Mabel electroplating filter can be flexibly configured with a variety of filter materials, such as cartridge type, filter paper type, etc., which not only simplifies the operation process, but also facilitates daily cleaning and maintenance. This design greatly saves labor costs and improves production efficiency.

High-temperature resistant characteristics, adapt to a variety of process requirements: Although the main body of the filter drum is made of PP plastic, which is suitable for working environments below 70℃, Mabel electroplating filter also provides titanium beam ring set as an upgrade option, which further broadens the applicable temperature range of the equipment and ensures that it remains stable and reliable under high temperature environments in the chrome plating process.

Environmental protection and energy saving, leading green production: The application of shaftless seal magnetic drive pump not only effectively prevents idling leakage and reduces environmental pollution, but also supports 24-hour waterless idling and reduces energy consumption, which is in line with the concept of green production of modern enterprises.

In the plastic plating process of stationery processing factory, Mabel plating filter has become an important force to improve product quality, guarantee production safety and promote process innovation with its excellent pressure resistance, high precision filtration effect, easy operation experience and environmental protection and energy saving design concept. Choosing Mabel electroplating filter is choosing the future of high efficiency, reliability and quality. Let's join hands to create and lead a new wave of development in the stationery processing industry!