As the core medium in the plating process, plating bath solution, its water quality characteristics and conveying needs are crucial to the entire plating process. Mabel Pumps, with its deep industry experience and expertise, provides a series of efficient and stable pumping solutions for the plating industry.

Electroplating bath liquid is a special liquid with complex composition, containing a variety of heavy metal ions and organic matter. Among them, the high concentration of heavy metal ions such as chromium, nickel, zinc, etc., not only the concentration is high, but also has the characteristics of toxicity and difficult to degrade. In addition, the high concentration of organic matter in the electroplating bath and the fluctuation of acidity and alkalinity are also its significant features. These characteristics require that the pump must have good corrosion resistance, stability and adaptability.

Plating bath liquid is widely used in metal products, plastic products, semiconductor manufacturing and aerospace and other fields. In these fields, plating bath solution plays multiple roles such as anti-corrosion, beautification and hardness improvement. Therefore, for the transportation of electroplating bath liquid, not only do we need pumps with high efficiency and stable performance, but we also need to consider its impact on product quality.

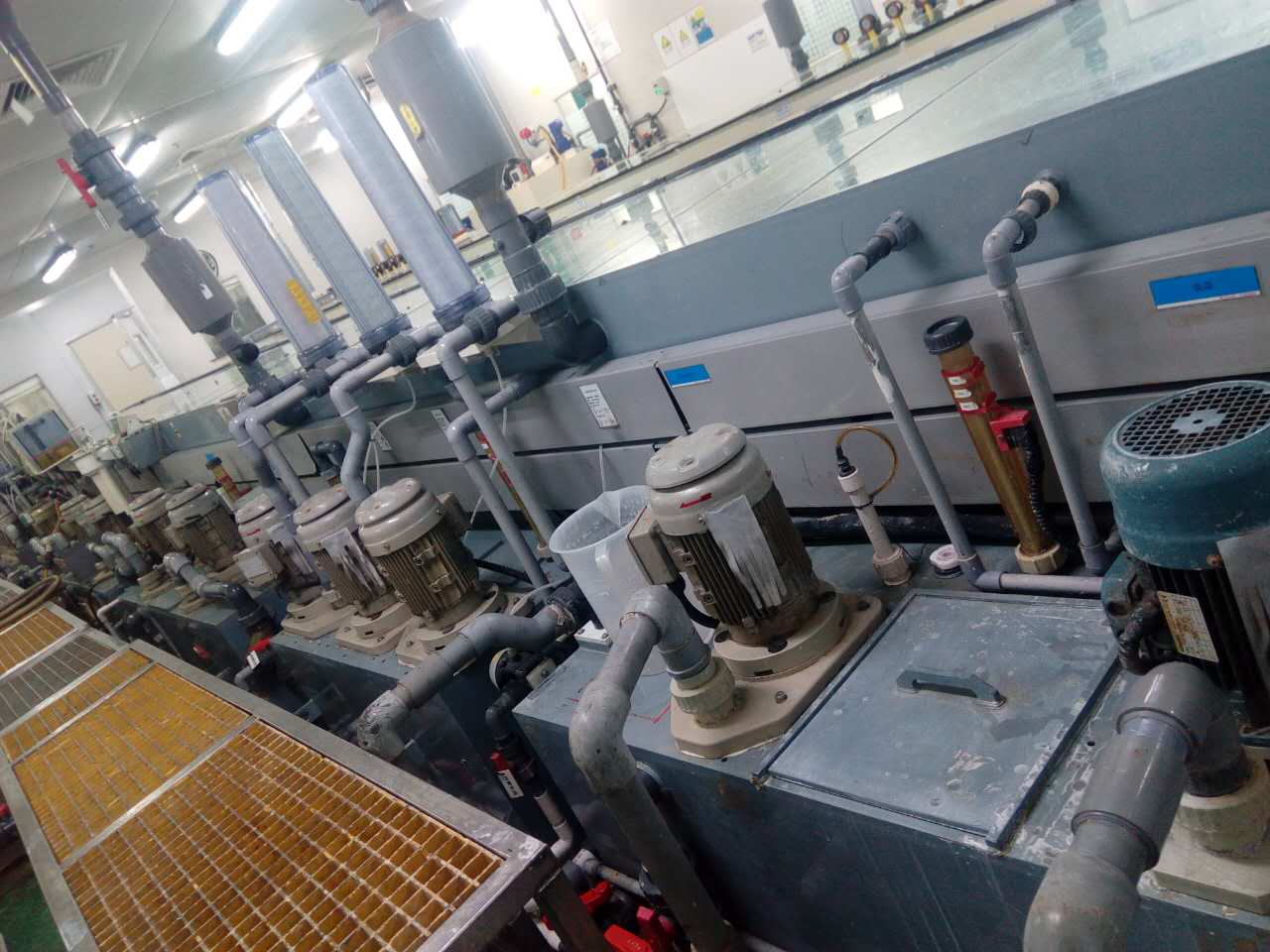

Aiming at the water quality characteristics and application requirements of electroplating bath liquid, Mabel pump industry has launched a series of professional pumping products. These products adopt advanced materials and processes, have excellent corrosion resistance and stability, and can operate stably for a long time without being eroded by chemicals in electroplating bath liquid. Meanwhile, Mabel's products also have high efficient conveying capacity and precise flow control function, which can meet the needs of different processes for plating tank liquid conveying.

A metal products manufacturer in Jinhua, after adopting Mabel Pump's electroplating tank solution, not only improved production efficiency, but also significantly reduced the failure rate and maintenance costs. The enterprise said that Mabel's products not only have stable and reliable performance, but also have thoughtful and timely after-sales service, which provides a strong guarantee for its production.

In addition, Mabel pump industry is also actively involved in a number of electroplating industry project cooperation, for many enterprises to provide high-quality pumping solutions. These successful cases not only proved the professional ability of Mabel Pump in the field of electroplating tank liquid transfer, but also won a wide range of praise and trust for it.

In a word, Mabel Pump provides efficient and stable pumping solutions for electroplating industry with its professional technical strength and rich industry experience. Whether facing the complex and changing characteristics of electroplating bath water quality or the application needs of different fields, Mabel Pump can provide customized solutions to help enterprises achieve more efficient and environmentally friendly production goals.