Acid and alkali resistant vertical pump is also known as in-tank submerged pump, with the advantages of acid and alkali resistance, corrosion resistance, high operating efficiency, long service life, reasonable institutional design, easy maintenance, etc., which is widely loved by customers. So what is the main use of acid and alkali resistant vertical pumps? With those equipment with the use of it? Let Mabel introduce it for you!

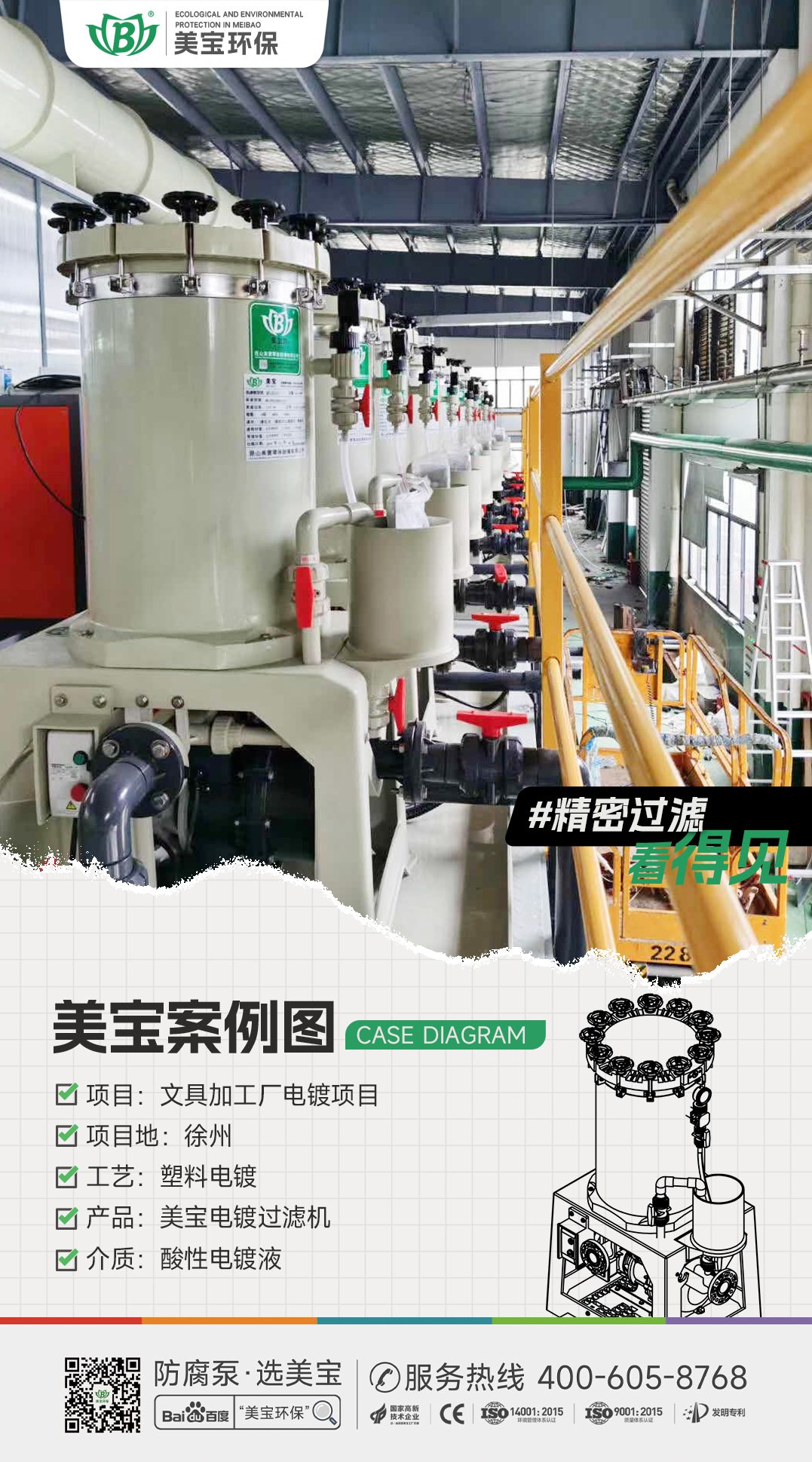

1. Can be combined with the use of filters, conveying a variety of chemical solutions, can be used in combination with chemical solution filters, suitable for a variety of chemical plating solution circulation conveyance, conveying temperature-resistant or crystalline chemical liquids, according to the chemical nature of the conveyance of the material selected is also different.

2. It can be used for the circulating conveying of PC board etching solution. Convenient installation in slot, anti-high pressure, no leakage and easy maintenance. It can be customised according to the depth of the customer's slot. 700- 1500mm, all the liquid-jointed parts of the pump are made of corrosion-resistant FRPP, CFRPP, PVDF, depending on the choice of chemical solution.

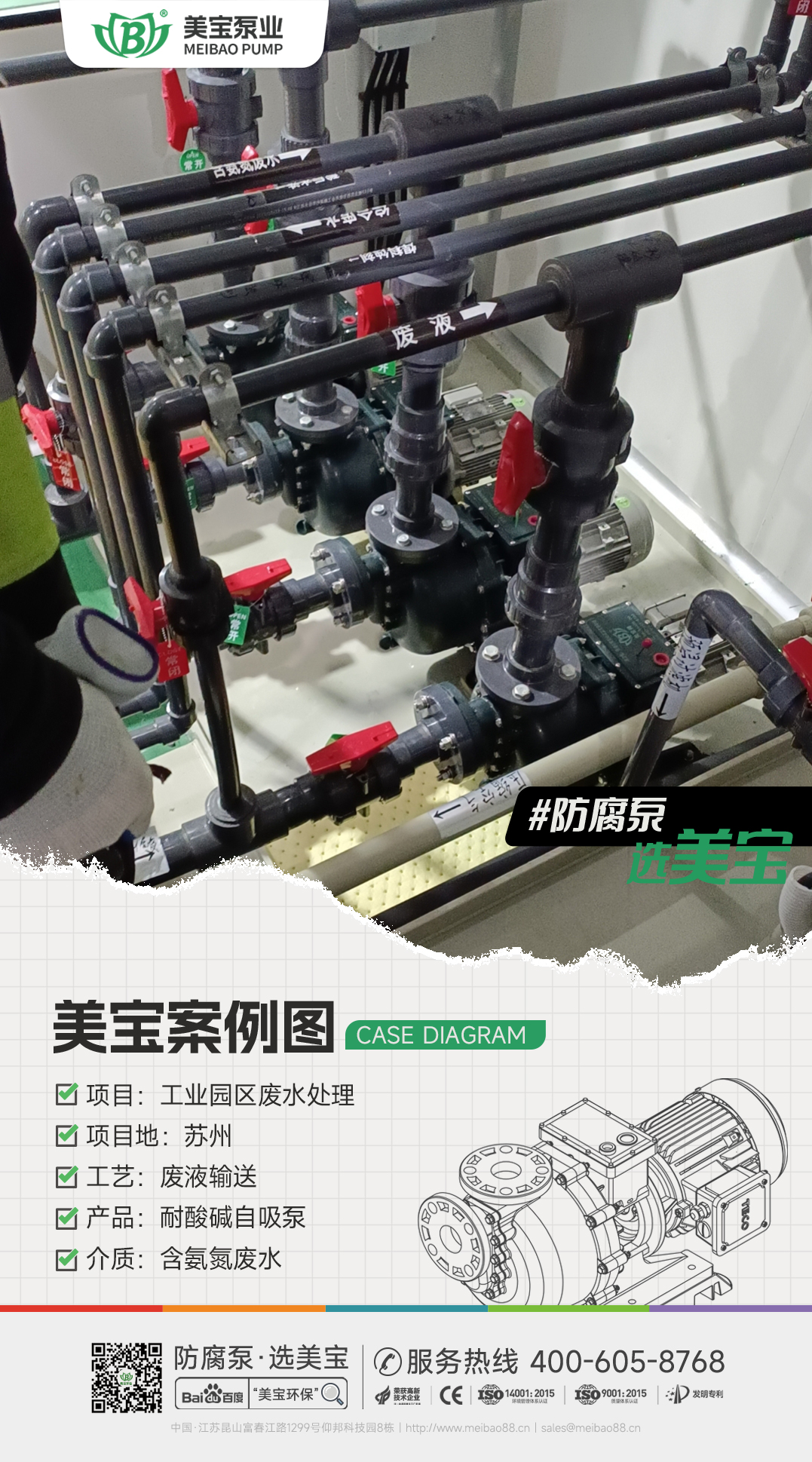

3.Conveying operation of wastewater treatment equipment. Adopting dry liquid seal design, anti-leakage and anti-corrosion effect of acid gas is remarkable. In the case of rising pressure in the pump, it cuts off the overflowing liquid, and when it stops, there will be no leakage of liquid backflow and damage to the pump body.

4. It can be used for spray cleaning operation of cleaning tower. Vertical pumps are available in various calibres and outputs, customized according to site conditions. Mould opening, check whether the equipment is complete.

5. It can be used as a heat exchange cycle and can be used for combined filter operation. New one-piece moulding impeller embedded structure, which greatly strengthens the strength of the impeller and prolongs the service life. Resistant to high temperature and pressure, not easy to be damaged.

6. All kinds of liquid circulating and conveying work in chemical mixing tank or reverse filtration tank. The vertical pump is made of corrosion-resistant FRPP, CFRPP, PVDF, which can convey acid and alkali corrosive media.